Repair or Maintenance, Choose wisely

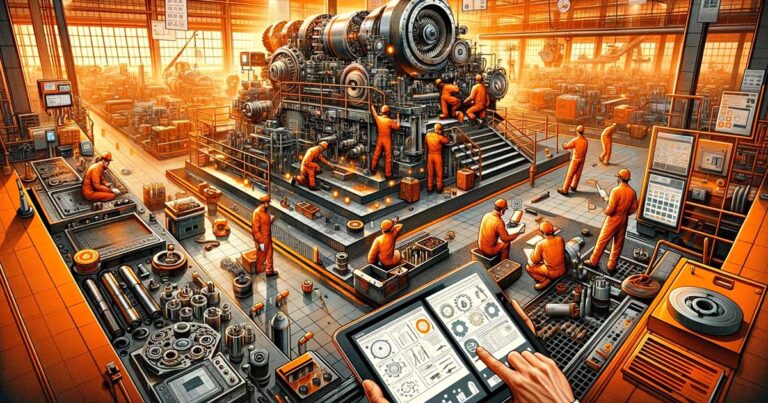

Maintenance and repair are two crucial aspects of any machine, whether it is a car, home appliances, or any other device. Many people tend to use these two terms interchangeably, but they are not the same. Maintenance refers to the routine care and upkeep of a device to keep it functioning optimally, while repair is…