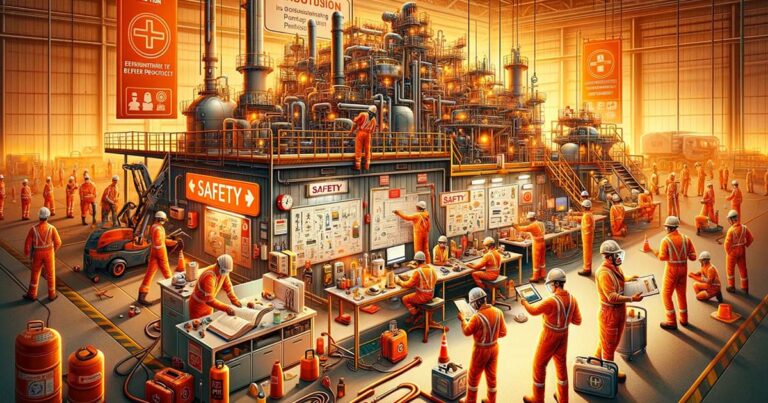

Introduction

Maintenance is a critical aspect of any industrial facility or manufacturing plant. Proper maintenance helps to ensure that equipment and machinery are operating efficiently and effectively, reducing the risk of breakdowns and downtime. However, maintenance can be a time-consuming and expensive process, especially when it comes to safety procedures. Fortunately, safety automation can help improve maintenance efficiency while maintaining a safe work environment.

What is Safety Automation?

Safety automation refers to the use of advanced technology to automate safety procedures and protocols. It involves the use of sensors, cameras, and other devices to monitor and control potentially hazardous activities and conditions in the workplace. Safety automation is designed to prevent accidents and injuries by providing a safe and reliable work environment.

How Safety Automation Improves Maintenance Efficiency

Safety automation can have a significant impact on maintenance efficiency by streamlining safety procedures and reducing the time and effort required to perform maintenance tasks. Here are some ways safety automation can improve maintenance efficiency:

1. Reduced Risk of Accidents and Injuries:

Safety automation helps to identify and control hazardous conditions before they cause accidents or injuries. By reducing the risk of accidents and injuries, maintenance personnel can work more safely and efficiently.

2. Increased Equipment Uptime:

Equipment downtime can be a significant drain on maintenance resources. Safety automation can help to prevent equipment breakdowns and prolong the life of equipment, resulting in increased uptime and reduced maintenance costs.

3. Improved Predictive Maintenance:

Safety automation can provide valuable data and insights into equipment performance and maintenance requirements. By monitoring equipment and identifying potential issues early on, maintenance personnel can perform proactive maintenance, reducing the need for reactive maintenance and minimizing downtime.

4. Enhanced Maintenance Planning and Scheduling:

Safety automation can help to optimize maintenance planning and scheduling. By providing real-time data on equipment performance and maintenance needs, maintenance personnel can prioritize and schedule maintenance tasks more efficiently.

5. Improved Compliance:

Safety automation can help ensure compliance with safety regulations and industry standards. By automating safety procedures and protocols, facilities can minimize the risk of non-compliance and associated penalties and fines.

Implementing Safety Automation

Implementing safety automation requires careful planning and consideration of several factors. First, it is essential to identify potential hazards and determine which safety procedures can be automated. Next, it is crucial to select the appropriate technology and devices to monitor and control these hazards. Finally, it is essential to train maintenance personnel on the proper use of safety automation technology and procedures.

Conclusion

In conclusion, safety automation can have a significant impact on maintenance efficiency and the safety of maintenance personnel. By streamlining safety procedures and reducing the time and effort required to perform maintenance tasks, safety automation can increase equipment uptime, improve predictive maintenance, enhance maintenance planning and scheduling, and improve compliance with safety regulations and industry standards. While implementing safety automation requires careful planning and consideration, the benefits to maintenance efficiency and personnel safety are well worth the effort.